What: automated “lights out” manufacturing

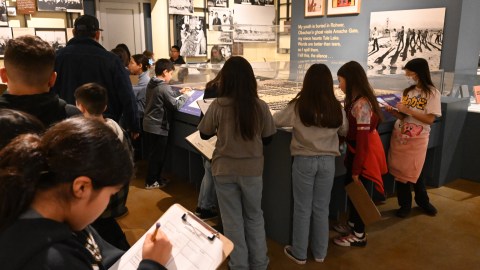

Why museums should care: disruptions to labor and increasing economic inequality impact our communities and our audiences, as well as museums’ own financial bottom line.

Many researchers predict that automation will result in massive labor displacement over the next couple of decades. According to researchers at MIT, each robot added to US workplaces reduces the workforce by 5.6humans, and every robot that is added per 1,000 humanworkers results in wages dropping by as much as 0.25 to 0.5 percent. Many of these robots are used in industrial manufacturing–making automobiles, manufacturing electronics or producing chemicals and plastics. Now artificial intelligence (AI) is fueling a new round of labor disruption in fields ranging from manufacturing and retail to law to medicine. A widely cited study from Oxford University projected that automation powered by AI will contribute to the loss of up to 47% of all jobs in the US in the next 20 years.

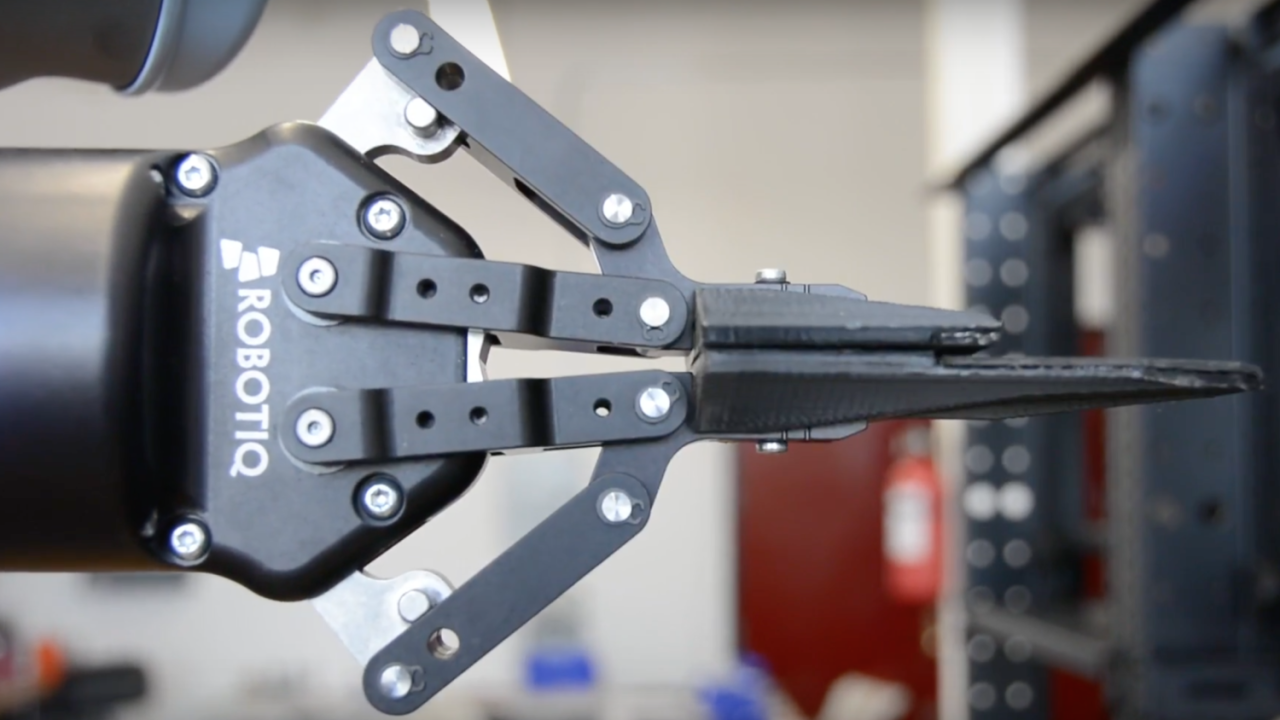

As we contemplate a future with fewer solid blue collar manufacturing jobs support a middle class, the spread of small scale, distributed, digital manufacturing has been hailed as one potential producer of new jobs. Digital design plus maker-friendly technologies such as 3-D scanning and printing fuel the creation of small businesses–and small businesses account for almost fifty percent of employment. But as the following video demonstrated, these small businesses are not immune to robotic labor disruption.

Payroll can account for thirty percent of a small businesses gross income–what small business owner could resist the prospect of a robotic employee that can work 24 hours a day (supporting so-called “lights-out manufacturing”), doesn’t require health insurance and doesn’t take sick leave?